In the world of product development, speed and precision are paramount. Traditional prototyping methods, which rely on materials like wood, metal, or plastic, can be time-consuming and expensive. However, with the rise of 3D printing, prototyping has become faster, more affordable, and more accurate.

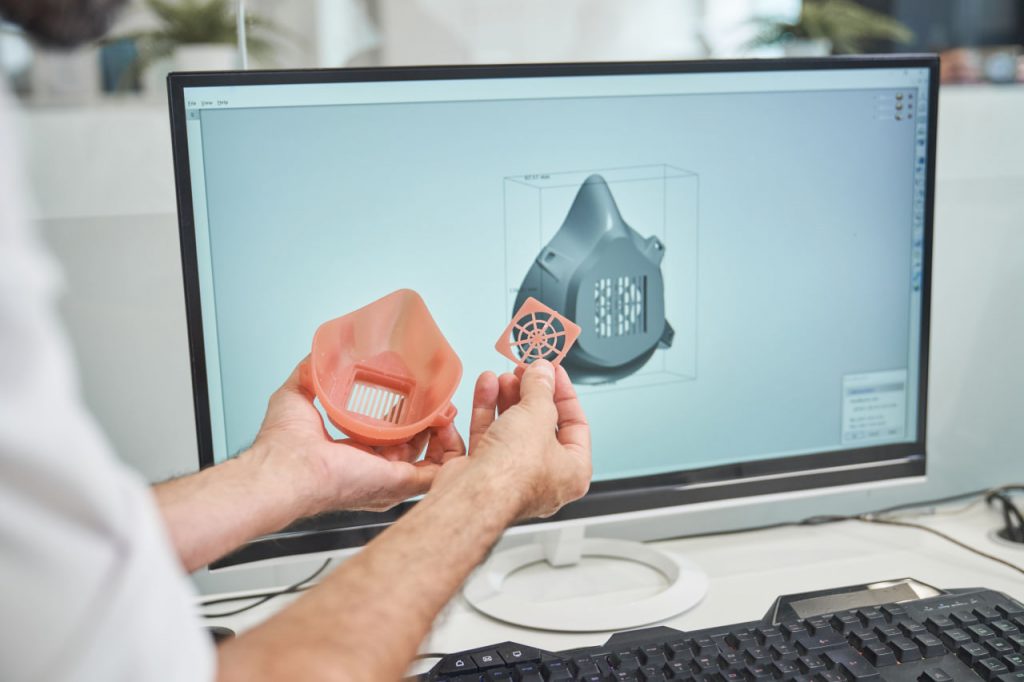

3D printing allows businesses to create highly detailed prototypes with complex geometries that were once impossible to produce with traditional manufacturing methods. This has greatly accelerated the product development cycle, allowing companies to test their designs quickly, make adjustments, and refine their products in real time.

Whether you’re a startup or a large corporation, 3D printing can offer significant advantages in reducing time-to-market, lowering costs, and increasing design flexibility. Rapid prototyping also gives businesses the ability to test products under real-world conditions before committing to mass production. This reduces the risk of failure and ensures that products meet customer expectations.

Moreover, 3D printing technology enables iterative design, which is particularly valuable in industries like automotive, consumer electronics, and medical devices. Designers and engineers can rapidly produce multiple versions of a prototype to identify the most effective and efficient design.

Conclusion

As the technology behind 3D printing continues to improve, its applications in prototyping and product development will only grow. The ability to quickly create and test prototypes allows businesses to innovate faster, reduce costs, and increase product quality. Embracing 3D printing for prototyping is a smart choice for companies looking to stay competitive in a rapidly evolving market while delivering high-quality products that meet customer needs.